云开·体育全站apply(kaiyun)(中国)官方网站平台

Jiangsu Shengli Centrifuge Manufacturing Co., Ltd.

Work hard and be honest

Automatic discharge centrifuge/Gypsum calcium centrifuge

云开·体育全站apply(kaiyun)(中国)官方网站平台

Jiangsu Shengli Centrifuge Manufacturing Co., Ltd.

Work hard and be honest

Automatic discharge centrifuge/Gypsum calcium centrifuge

PRODUCTS

PRODUCTS

Shengli Centrifuge Manufacturing

PLD series flatbed full-automatic bottom unloading centrifuge

.jpg)

Features and uses

■ Automatic frequency converter to control speed.

■ It has all advantages of common vertical scraper down discharging centrifuge.

■ Full-automatic operation for hanging bag falling off and reset.

■ The filter bag can move up and down inside the drum to produce oscillation effect and remove the remnant filter cake throughly.

■ Big clamshell or shell whole reversible type are achievable according to users' demands.

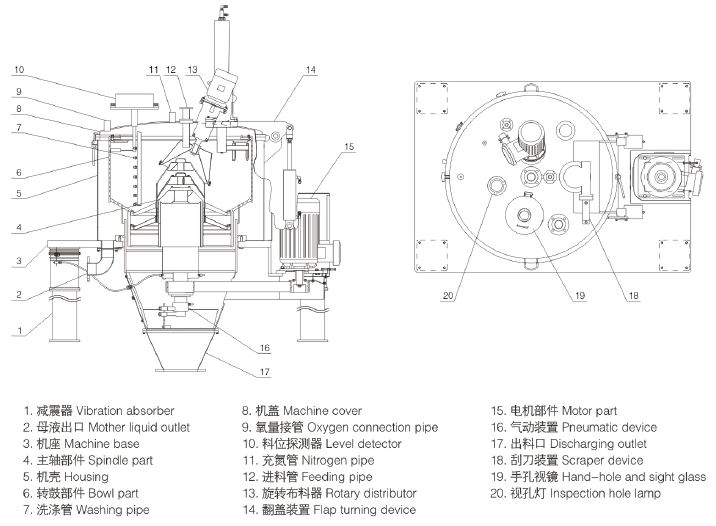

Structure diagram and principle

1. Working principle

During the process of discharging, the scraper acts, under the impact of which most material are discharged through the blanking hole on the bottom of drum to the outside. The remnant material layer will generate oscillation effect by the influence of automatic hanging bag mechanism inside the drum and then the remnant material layer will be removed.

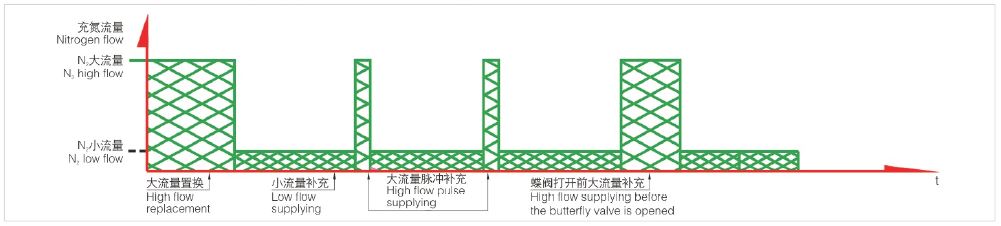

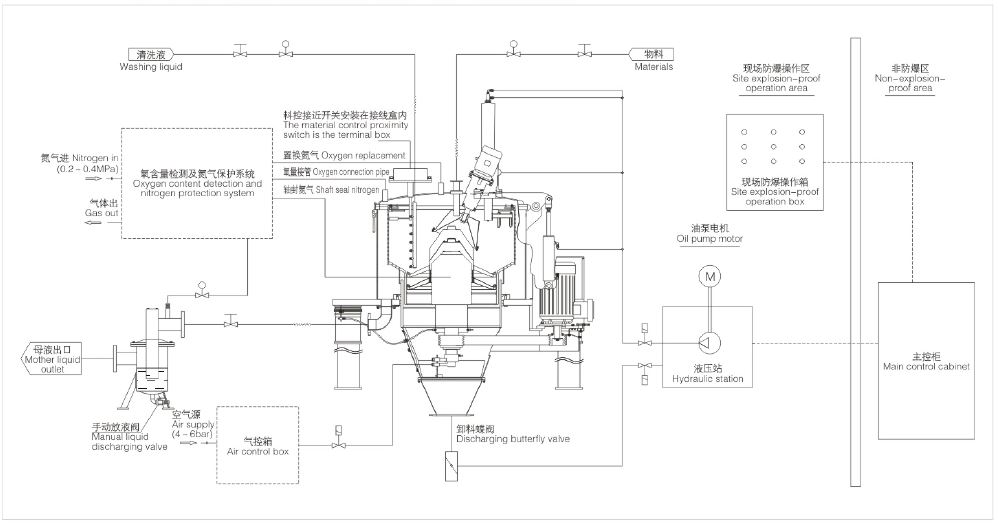

2. Explosion-proof working principle

The explosion-proof bag pulling centrifuge is manufactured according to the explosion-proof standard. Before the centrifuge is started, high flow nitrogen replacement is carried out. The gas inside the centrifuge is ensured to be insert through adopting oxygen content detection, pressure test and other ways, so as to meet the centrifuge running requirements. After the equipment runs, the oxygen content is monitored in a dynamic manner and high flow nitrogen replacement or low flow low pressure nitrogen supplying is carried out, so as to ensure that the equipment meets the explosion-proof running requirements

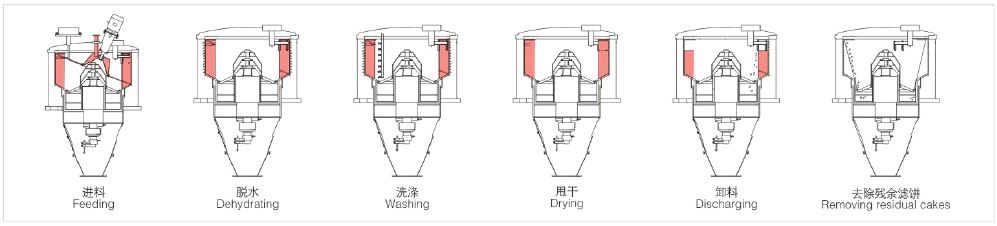

3. Schematic diagram of working process

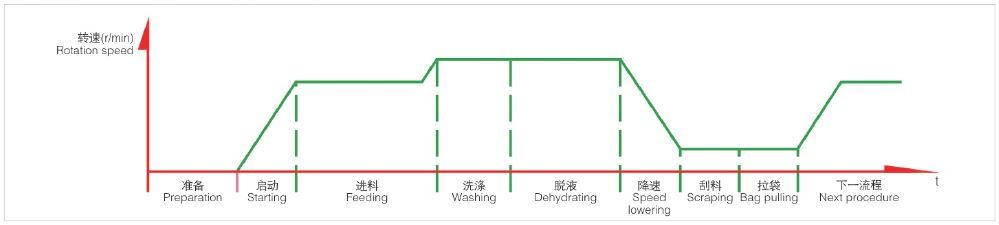

4. Working process of centrifuge

5. Nitrogen replacement and replenishment process

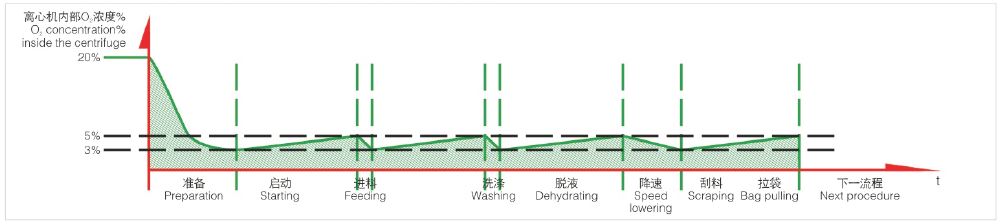

6. Oxygen concentration in the inner cavity of the centrifuge

7. Explosion-proof process drawing of bag-drawing centrifuge

8. Explosion-proof field application diagram of bag-drawing centrifuge

.jpg)

The main technical parameters

| Item | Model | |||||

| PLD800 | PLD 1000 | PLD 1250 | PLD1360 | PLD1600 | PLD1800 | |

| Drum diameter(mm) | 800 | 1000 | 1250 | 1360 | 1600 | 1800 |

| Drum working highly(mm) | 400 | 450 | 700 | 800 | 800 | 1100 |

| Drum working volume(L) | 100 | 160 | 400 | 530 | 800 | 1250 |

| Maximum loading limit(kg) | 140 | 215 | 500 | 680 | 1120 | 1750 |

| Durm speed(r/min) | 1200/1500 | 1000/1200 | 1000/1200 | 970/1150 | 850/1050 | 800 |

| Filtration area(m2) | 1.0 | 1.41 | 2.47 | 3.41 | 4.0 | 6.22 |

| Separation factor(ω2r/ ɡ) | 645/1006 | 560/804 | 700/1006 | 715/1006 | 647/986 | 645 |

| Motor power(kw) | 7.5/11 | 11/15 | 22/30 | 30/37 | 37/55 | 55 |

| Overall weight(kg) | 2000 | 3500 | 5000 | 8500 | 12000 | 17000 |

| Physical size(mm) | 1800×1300×2000 | 1950×1600×2100 | 2300×1800×2400/2700 | 2350×1900×2700 | 2980×2250×3000/3200 | 3300×2500×3850 |

HOME | ABOUT US | PRODUCTS | NEWS | SERVICE | FACTORY | HONORS | ORDER | CONTACT | 中文版

Copyright(C)2021, Jiangsu Shengli Centrifuge Manufacturing Co., Ltd. All Rights Reserved. Supported by ChinaChemNet ChemNet Toocle Copyright Notice 备案序号:苏ICP备16066832号